COURSE OVERVIEW

ME0420 : Turbo Expander Operation, Performance, Maintenance & Troubleshooting

OVERVIEW

| COURSE TITLE | : | ME0420 : Turbo Expander Operation, Performance, Maintenance & Troubleshooting |

| COURSE DATE | : | Jul 08 - Jul 11 2024 |

| DURATION | : | 4 Days |

| INSTRUCTOR | : | Mr. Dimitry Rovas |

| VENUE | : | Abu Dhabi, UAE |

| COURSE FEE | : | $ 4500 |

| Request For Course | ||

OTHER SCHEDULED DATES

| Date | : | Jun 22 - Jun 26 2025 (5 Days) | Location | : | Al Khobar, KSA | Classroom Fee (US$) | : | $ 5500 | Course Info |

| Date | : | Dec 14 - Dec 18 2025 (5 Days) | Location | : | Dubai, UAE | Classroom Fee (US$) | : | $ 5500 | Course Info |

Course Description

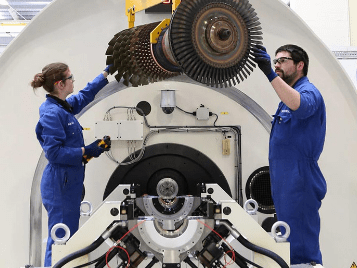

This practical and highly-interactive course includes real-life case studies where participants will be engaged in a series of interactive small groups and class workshops. Turbo-expanders have been used for decades in hundreds of applications and are used to drive generators, pumps and compressors in the most demanding of applications. Turboexpanders are manufactured in both radial inflow (centrifugal) and axial configurations in sizes ranging from a fraction of a HP up to 50,000 HP. The turboexpander is a centrifugal or axial flow turbine through which a high pressure gas is expanded to produce work that is typically used to drive a compressor. Because work is extracted from the expanding high pressure gas, the expansion is isentropic and the low pressure exhaust gas from the turbine is at a very low temperature, often as low as 200 K (-100 ?F) or less. Turbo-expanders are essential components in air separation plants; cryogenic processes; LNG plants; natural gas and propane pressure letdown applications - gas plants & pipeline compressor stations; geothermal applications; and waste heat recovery systems. It is common to have two or more turbo-expanders driving a single generator, pump or compressor. High-pressure turboexpanders, usually installed in pairs, are typically used to provide refrigeration for the production of cryogenic liquids. The expander extracts work from a high-pressure gas stream providing refrigeration to the process. The work removed from the gas stream by the expander is used to provide compression power to cycle. These applications demand high efficiency and reliability at a low installed cost. The efficiency of the turboexpander has a significant impact on the cost of the cryogenic liquid produced.This course is designed to provide participants with a complete and up-to-date overview of the turboexpanders from the basic knowledge and applications to the maintenance and troubleshooting techniques. The course will cover turboexpander fundamentals; application of cryogenic turboexpanders: processes; applications of hot gas turboexpanders; overview of turboexpander construction features; rotor dynamics; construction materials; fabrication issues; installation guides; turboexpander maintenance; failure analysis and troubleshooting.

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies:

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable:

| Certificates | : | Only soft copy certificates will be issued |

| Training Materials | : | Only soft copy materials will be issued |

| Training Methodology | : | 80% theory, 20% practical |

| Training Program | : | 4 hours per day, from 09:30 to 13:30 |

RELATED COURSES

ME0027 : Centrifugal Pump Selection, Construction, Operation, Maintenance, Repair & Troubleshooting

- Date: Jan 19 - Jan 23 / 3 Days

- Location: Dubai, UAE

- Course Details Register

ME0045 : ASME VIII Pressure Vessel Design, Fabrication & Testing

- Date: Jan 19 - Jan 23 / 3 Days

- Location: Dubai, UAE

- Course Details Register

ME0172 : INDUSTRIAL EQUIPMENT & TURBOMACHINERY: Pumps, Compressors, Turbines & Motors: Selection, Sizing, Applications, Operation, Diagnostic Testing, Troubleshooting, Maintenance & Failure Analysis

- Date: Jan 19 - Jan 23 / 3 Days

- Location: Cairo, Egypt

- Course Details Register

ME0615 : Operation, Maintenance & Troubleshooting of Pumps & Compressors

- Date: Jan 19 - Jan 23 / 3 Days

- Location: Dubai, UAE

- Course Details Register