COURSE OVERVIEW

FE0433 : Welding Defects Analysis

OVERVIEW

| COURSE TITLE | : | FE0433 : Welding Defects Analysis |

| COURSE DATE | : | Jan 26 - Jan 30 2025 |

| DURATION | : | 5 Days |

| INSTRUCTOR | : | Mr. Mohamed Kader (FE) |

| VENUE | : | Dubai, UAE |

| COURSE FEE | : | $ 5500 |

| Request For Course Outline | ||

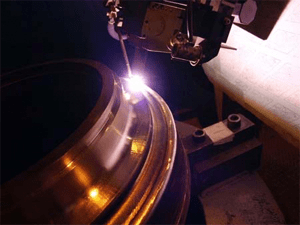

Course Description

This practical and highly-interactive course includes practical sessions and exercises where participants carryout welding inspection. Theory learnt in the class will be applied using our state-of-the-art simulators.

This course is designed to provide participants with an up-to-date overview on welding defects analysis. It covers the identification of various welding imperfections and defects; the relevant welding technology related to visual inspection, documentation in welding and code and standards related to inspection requirements; the proper inspection of parent materials and consumables; the visual inspection of welds; the reporting and assessing with specified acceptance criteria; the factors which influence the quality of fusion welds in steels; and the characteristics of commonly used welding process in relation to quality control and specifications of drawing instructions and symbols.

The course will further discuss the validity of a welding procedure; the origin of weld defects; the features of a fracture surface; the detailed reports plan, the use of skilled inspectors and NDT personnel; the various types of weld defects and how it is expected to appear on a radiographic image and what causes them; the gas pour, linear porosity and lack of fusion; and the various types of cracks and weld repair methods.

During the course, participants will be able to cover the theoretical background of phased array applications; the scan data for location and size of defects in typical welded butt joints; the basic theory of X- and gamma radiography and radiograph; the proper radiographic techniques and the difference between film faults and defect indications; the basic principles of magnetic particles inspection methods; the magnetic particle inspection and detection of cracks, surface and near-surface in welds; the PWSCC effects on reactor welds; the reactor vessel nozzle weld problems, the hellion time effect on aging reactor welds; and the stream generator weld problems.

link to course overview PDF

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies:

LecturesPractical Workshops & Work Presentations

Hands-on Practical Exercises & Case Studies

Simulators (Hardware & Software) & Videos

In an unlikely event, the course instructor may modify the above training methodology for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable:

| Certificates | : | Only soft copy certificates will be issued |

| Training Materials | : | Only soft copy materials will be issued |

| Training Methodology | : | 80% theory, 20% practical |

| Training Program | : | 4 hours per day, from 09:30 to 13:30 |

RELATED COURSES

FE1019 : Designing for Corrosion Control in Refinery

- Date: Jan 18 - Jan 22 / 3 Days

- Location: Al Khobar, KSA

- Course Details Register

FE0430 : Welding Engineering & Technology: Welding, Fabrication and Inspection (AWS, ASME and API Codes)

- Date: Jan 18 - Jan 22 / 3 Days

- Location: Cairo, Egypt

- Course Details Register

FE0930 : API 577: Welding Inspection and Metallurgy

- Date: Jan 18 - Jan 22 / 3 Days

- Location: Dubai, UAE

- Course Details Register

FE0089 : API Codes (Rotary and Static Equipment)

- Date: Jan 18 - Jan 22 / 3 Days

- Location: Al Khobar, KSA

- Course Details Register