COURSE OVERVIEW

ME0100 : Valve Technology: Selection, Installation, Upgrading, Inspection, Maintenance, Repair & Troubleshooting

OVERVIEW

| COURSE TITLE | : | ME0100 : Valve Technology: Selection, Installation, Upgrading, Inspection, Maintenance, Repair & Troubleshooting |

| COURSE DATE | : | Feb 02 - Feb 06 2025 |

| DURATION | : | 5 Days |

| INSTRUCTOR | : | Mr. Daniel Williams |

| VENUE | : | Dubai, UAE |

| COURSE FEE | : | $ 5500 |

| Request For Course Outline | ||

Course Description

This course is designed to provide participants with a detailed and up-to-date overview of Valve Selection, Installation & Maintenance. It covers the lubrication fitting and categorizing valves based on their function; the valve symbols, hydraulic pneumatic valves, motor, cylinders and directional control valves; the solenoid valve, typical valve and other valve designs; the various types of pressure control valves, check valves and control valve; and the characteristics of valve and control valve selection and sizing.

Further, the course will also discuss the control valve performance, process considerations, actuators and positioners; the fundamentals of pressure relief devices including the advantages and disadvantages of conventional valve and balanced bellows valve; the piston type pilot operated safety relief valve; the wetted area, heat absorption, vaporization rate and relief vent area; the causes of chatter, staggered PSV’s and valve critical inspection, maintenance and testing; and the PRV repair and non-destructive testing including disc dismantling, assembly and disassembly.

This course is designed to provide participants with a detailed and up-to-date overview of Valve Selection, Installation & Maintenance. It covers the lubrication fitting and categorizing valves based on their function; the valve symbols, hydraulic pneumatic valves, motor, cylinders and directional control valves; the solenoid valve, typical valve and other valve designs; the various types of pressure control valves, check valves and control valve; and the characteristics of valve and control valve selection and sizing.

Further, the course will also discuss the control valve performance, process considerations, actuators and positioners; the fundamentals of pressure relief devices including the advantages and disadvantages of conventional valve and balanced bellows valve; the piston type pilot operated safety relief valve; the wetted area, heat absorption, vaporization rate and relief vent area; the causes of chatter, staggered PSV’s and valve critical inspection, maintenance and testing; and the PRV repair and non-destructive testing including disc dismantling, assembly and disassembly.

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies:

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable:

| Certificates | : | Only soft copy certificates will be issued |

| Training Materials | : | Only soft copy materials will be issued |

| Training Methodology | : | 80% theory, 20% practical |

| Training Program | : | 4 hours per day, from 09:30 to 13:30 |

RELATED COURSES

ME0313 : Steam Turbine Operation & Maintenance

- Date: Feb 23 - Feb 27 / 3 Days

- Location: Al Khobar, KSA

- Course Details Register

ME0791 : Screw Compressor Overhauling

- Date: Feb 23 - Feb 27 / 3 Days

- Location: Al Khobar, KSA

- Course Details Register

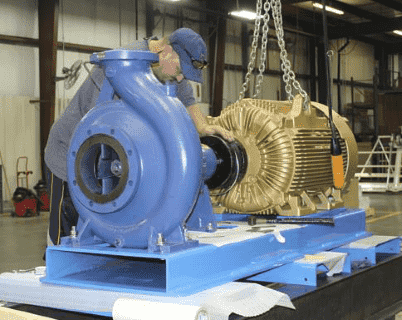

ME0562 : Pump Selection, Installation, Performance & Control

- Date: Feb 23 - Feb 27 / 3 Days

- Location: Al Khobar, KSA

- Course Details Register

ME0027 : Centrifugal Pump Selection, Construction, Operation, Maintenance, Repair & Troubleshooting

- Date: Feb 23 - Feb 27 / 3 Days

- Location: Cairo, Egypt

- Course Details Register