COURSE OVERVIEW

FE0110 : Fitness-for-Service, Remaining Life Assessment & Repair of Pressure Equipment & Piping (API-579/ASME FFS-1 & PCC-2 Standards)

OVERVIEW

| COURSE TITLE | : | FE0110 : Fitness-for-Service, Remaining Life Assessment & Repair of Pressure Equipment & Piping (API-579/ASME FFS-1 & PCC-2 Standards) |

| COURSE DATE | : | Feb 02 - Feb 06 2025 |

| DURATION | : | 5 Days |

| INSTRUCTOR | : | Mr. Steve Magalios |

| VENUE | : | Dubai, UAE |

| COURSE FEE | : | $ 5500 |

| Request For Course Outline | ||

Course Description

This practical and highly-interactive course includes real-life case studies and exercises where participants will be engaged in a series of interactive small groups and class workshops.

The latest ASME Post-Construction Code is an extension of the current API standards for Risk-Based-Inspection (API 580, API 581), Fitness-For-Service assessment (API 579), Damage Mechanisms (API 571) and repairs. They are a practical and important addition to the ASME design and construction codes, their objective is to prevent failures by timely detection and analysis of degraded conditions, and application of the right repair technique.

In this highly practical course, participants will learn how to (1) plan inspections, (2) evaluate inspection results and calculate the remaining life of corroded and degraded equipment, and (3) select and implement the right repair by applying the new ASME Post-Construction Codes (PCC).

The course will follow the same outline as the ASME PCC Codes, making the course notes a practical and handy reference to illustrate and explain the various requirements of the new ASME PCC codes.

Further, the course will review the recommended practices of API 579 and API 571 and how they can be applied on Fitness-for-Service and damage mechanisms affecting process plant equipment.

The course covers general engineering assessment, damage mechanisms, and specific assessment procedures that include the fitness-for-service of equipment and materials of construction used in refining, petrochemical, and chemical industries. It also covers brittle fracture applications for low temperature refinery and petrochemical services, assessment of corrosion damage, assessment of blisters/laminations, and assessment of crack-like flaws, assessment of fire damage, and the Run-Repair-Replace decision-making process.

The participants will not only be able to apply the rules to calculate the remaining life of corroded and degraded equipment, and make run-or-repair decisions, but will also understand the historical and technical basis of the rules.

The course is illustrated through a large number of case studies and does involve some calculations (with a hand-held calculator) to calculate failure margins and remaining life.

link to course overview PDF

The latest ASME Post-Construction Code is an extension of the current API standards for Risk-Based-Inspection (API 580, API 581), Fitness-For-Service assessment (API 579), Damage Mechanisms (API 571) and repairs. They are a practical and important addition to the ASME design and construction codes, their objective is to prevent failures by timely detection and analysis of degraded conditions, and application of the right repair technique.

In this highly practical course, participants will learn how to (1) plan inspections, (2) evaluate inspection results and calculate the remaining life of corroded and degraded equipment, and (3) select and implement the right repair by applying the new ASME Post-Construction Codes (PCC).

The course will follow the same outline as the ASME PCC Codes, making the course notes a practical and handy reference to illustrate and explain the various requirements of the new ASME PCC codes.

Further, the course will review the recommended practices of API 579 and API 571 and how they can be applied on Fitness-for-Service and damage mechanisms affecting process plant equipment.

The course covers general engineering assessment, damage mechanisms, and specific assessment procedures that include the fitness-for-service of equipment and materials of construction used in refining, petrochemical, and chemical industries. It also covers brittle fracture applications for low temperature refinery and petrochemical services, assessment of corrosion damage, assessment of blisters/laminations, and assessment of crack-like flaws, assessment of fire damage, and the Run-Repair-Replace decision-making process.

The participants will not only be able to apply the rules to calculate the remaining life of corroded and degraded equipment, and make run-or-repair decisions, but will also understand the historical and technical basis of the rules.

The course is illustrated through a large number of case studies and does involve some calculations (with a hand-held calculator) to calculate failure margins and remaining life.

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies:

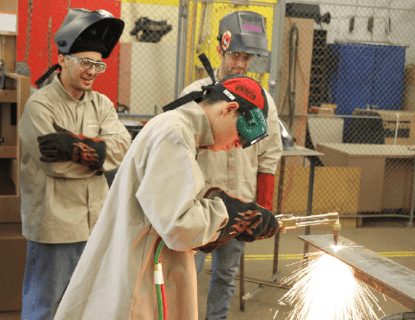

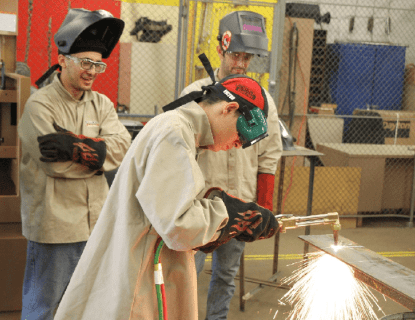

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable:

| Certificates | : | Only soft copy certificates will be issued |

| Training Materials | : | Only soft copy materials will be issued |

| Training Methodology | : | 80% theory, 20% practical |

| Training Program | : | 4 hours per day, from 09:30 to 13:30 |

RELATED COURSES

FE0430 : Welding Engineering and Technology: ASME IX Welding, Fabrication, Brazing, Inspection & Fusing Qualification

- Date: Feb 24 - Feb 28 / 3 Days

- Location: London, United Kingdom

- Course Details Register

FE0430 : Welding Technology: ASME IX Welding, Fabrication, Brazing, Inspection & Fusing Qualification

- Date: Feb 24 - Feb 28 / 3 Days

- Location: London, United Kingdom

- Course Details Register

FE0762 : Acoustic Emission Testing Level II Training & Certification (ASNT's, SNT-TC-1A)

- Date: Feb 23 - Feb 27 / 3 Days

- Location: Kuala Lumpur, Malaysia

- Course Details Register

FE0320 : Metallurgy, Corrosion and Prevention of Failures: Material Selection and Properties

- Date: Feb 23 - Feb 27 / 3 Days

- Location: Al Khobar, KSA

- Course Details Register