COURSE OVERVIEW

FE0040 : ASME B31 Piping & Pipeline Design, Construction, Inspection, Pigging, Maintenance, Repair & Integrity Assessment (ASME B31, API 570 & API 579 Standards)

OVERVIEW

| COURSE TITLE | : | FE0040 : ASME B31 Piping & Pipeline Design, Construction, Inspection, Pigging, Maintenance, Repair & Integrity Assessment (ASME B31, API 570 & API 579 Standards) |

| COURSE DATE | : | Feb 02 - Feb 06 2025 |

| DURATION | : | 5 Days |

| INSTRUCTOR | : | Mr. Den Bazley |

| VENUE | : | Doha, Qatar |

| COURSE FEE | : | $ 6000 |

| Request For Course Outline | ||

Course Description

This practical and highly-interactive course includes various practical sessions and exercises. Theory learnt will be applied using our state-of-the-art simulators.

This course provides a comprehensive coverage of the ASME B31 Code requirements. It has been completely revised, reorganized and updated, and includes descriptions of important new requirements of ASME B31, including the philosophy behind the changes. Further, the course has been enriched with the latest requirements of the API 570 and API 579.

General topics in the course include: Code organization and intent, pressure design, design for sustained loads including support design, flexibility analysis, equipment loads, expansion joints, supports and restraints, materials, fabrication, examination, testing, pigging, and, for existing piping & pipeline systems: risk-based inspection, pigging, maintenance, repair, rehabilitation, fitness-for-service and mechanical integrity.

Applications of these concepts, including simple hand analysis methods and computer-based analysis methods, will be demonstrated. Examples of the required analysis and sources of further information will be provided.

The course covers design, fabrication, examination and testing requirements of ASME B31. It covers Code requirements from design through start-up of new piping & pipeline systems, as well as standards for inspection, integrity and repair of piping & pipeline systems that have been in service, as provided in API 570 and API 579. The course covers the practical aspects of piping and pipeline integrity, maintenance and repair. Participants will be introduced to the technical basis of the ASME and API integrity rules, and their application to case studies and exercises. The participants will be able to recognize causes of degradation in-service, whether mechanically induced (pressure, vibration, fatigue, pressure transients, external damage) or due to corrosion (wall thinning, pitting, cracking), and apply integrity analysis techniques to make run-or-repair decisions.

The course provides a working knowledge of the Code, how it is organized, its intent, the basis for requirements, including both design and construction (fabrication, erection and testing) aspects. It provides a foundation of knowledge necessary for those responsible for assuring the mechanical integrity of existing systems, as well as those responsible for designing and constructing new systems. The participants will become knowledgeable in the technical basis and application of ASME B31.3, B31.4 and B31.8 piping codes, ASME B31G, API 570 and API 579 Fitness-for-Service and Flaw Evaluation.

link to course overview PDF

TRAINING METHODOLOGY

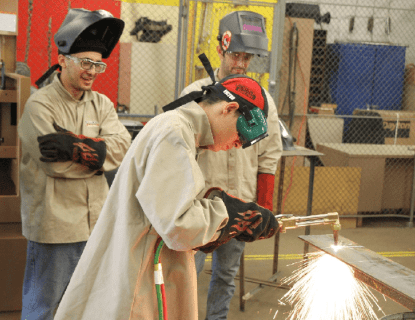

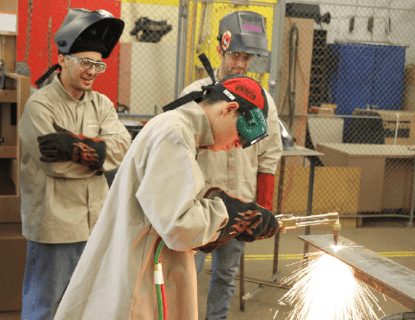

This interactive training course includes the following training methodologies:

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable:

| Certificates | : | Only soft copy certificates will be issued |

| Training Materials | : | Only soft copy materials will be issued |

| Training Methodology | : | 80% theory, 20% practical |

| Training Program | : | 4 hours per day, from 09:30 to 13:30 |

RELATED COURSES

FE0430 : Welding Technology: ASME IX Welding, Fabrication, Brazing, Inspection & Fusing Qualification

- Date: Feb 24 - Feb 28 / 3 Days

- Location: London, United Kingdom

- Course Details Register

FE0762 : Acoustic Emission Testing Level II Training & Certification (ASNT's, SNT-TC-1A)

- Date: Feb 23 - Feb 27 / 3 Days

- Location: Kuala Lumpur, Malaysia

- Course Details Register

FE0320 : Metallurgy, Corrosion and Prevention of Failures: Material Selection and Properties

- Date: Feb 23 - Feb 27 / 3 Days

- Location: Al Khobar, KSA

- Course Details Register

FE0430 : Welding Engineering and Technology: ASME IX Welding, Fabrication, Brazing, Inspection & Fusing Qualification

- Date: Feb 24 - Feb 28 / 3 Days

- Location: London, United Kingdom

- Course Details Register