COURSE OVERVIEW

FE0721 : ASME-V Non-Destructive Testing

OVERVIEW

| COURSE TITLE | : | FE0721 : ASME-V Non-Destructive Testing |

| COURSE DATE | : | Feb 02 - Feb 06 2025 |

| DURATION | : | 5 Days |

| INSTRUCTOR | : | Mr. Gert Viljoen |

| VENUE | : | Al Khobar, KSA |

| COURSE FEE | : | $ 5500 |

| Request For Course Outline | ||

Course Description

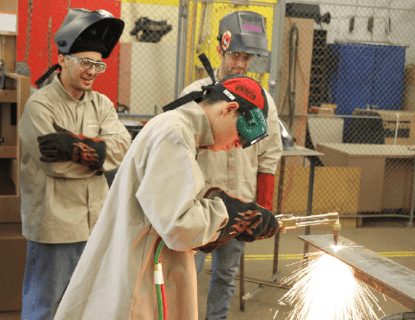

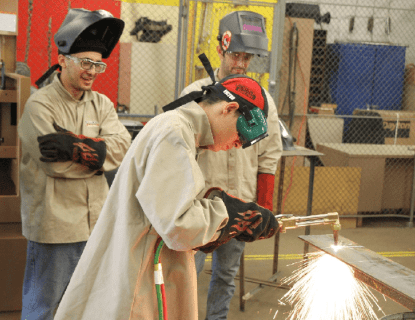

This practical and highly-interactive course includes various practical sessions and exercises. Theory learnt will be applied using our state-of-the-art simulators.

Non-destructive testing (NDT) is the process of inspecting, testing, or evaluating materials, components or assemblies for discontinuities, or differences in characteristics without destroying the serviceability of the part or system. In other words, when the inspection or test is completed the part can still be used. It’s a wide group of analysis techniques used to evaluate the properties of a material, part, product, weld, or system without causing damage.

Non-destructive testing is a commonly-used tool in forensic engineering, mechanical engineering, electrical engineering, civil engineering, systems engineering, aerospace and aeronautical engineering, and medical applications. The terms Non- Destructive Examination (NDE), Non-Destructive Inspection (NDI), and Non- Destructive Evaluation (NDE) are also commonly used to describe nondestructive testing methodology. It covers the various NDT methods and techniques such as liquid penetrant testing, magnetic particle testing, electromagnetic testing, ultrasonic testing method, radiographic testing, visual testing and other NDT methods and techniques.

This course is designed to provide participants with a detailed and up-up-to date overview of non-destructive testing. It covers the NDT approach including method selection, detecting discontinuities, surface, subsurface, contrast with destructive testing, interpretive technology, test variables, standards for comparison and application; the various techniques of liquid penetrant testing and its advantages, disadvantages, limitations, types, equipment, safety precaution and personnel requirements; the proper method of magnetic particle testing covering the advantages and disadvantages as well as the basic magnetic particle process, preparation of parts, magnetization, application, assessment of discontinuities and magnetic particle testing methods.

Further, the course will also cover the electromagnetic testing including the eddy current techniques and its principles as well as the factors affecting eddy current; the ultrasonic testing method including ultrasonic principles, detection of discontinuities, pulse-echo techniques and transmission techniques; the radiographic testing including the types of radiation, principles of radiography and the exposure factors; and the procedure of visual testing, other NDT methods and techniques and certification requirements.

link to course overview PDF

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies:

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable:

| Certificates | : | Only soft copy certificates will be issued |

| Training Materials | : | Only soft copy materials will be issued |

| Training Methodology | : | 80% theory, 20% practical |

| Training Program | : | 4 hours per day, from 09:30 to 13:30 |

RELATED COURSES

FE0430 : Welding Engineering and Technology: ASME IX Welding, Fabrication, Brazing, Inspection & Fusing Qualification

- Date: Feb 24 - Feb 28 / 3 Days

- Location: London, United Kingdom

- Course Details Register

FE0762 : Acoustic Emission Testing Level II Training & Certification (ASNT's, SNT-TC-1A)

- Date: Feb 23 - Feb 27 / 3 Days

- Location: Kuala Lumpur, Malaysia

- Course Details Register

FE0320 : Metallurgy, Corrosion and Prevention of Failures: Material Selection and Properties

- Date: Feb 23 - Feb 27 / 3 Days

- Location: Al Khobar, KSA

- Course Details Register

FE0430 : Welding Technology: ASME IX Welding, Fabrication, Brazing, Inspection & Fusing Qualification

- Date: Feb 24 - Feb 28 / 3 Days

- Location: London, United Kingdom

- Course Details Register