COURSE OVERVIEW

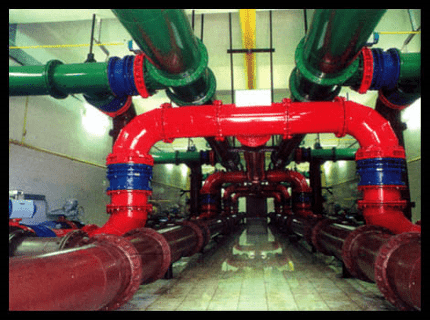

ME0630 : The Layout of Piping Systems & Process Equipment

OVERVIEW

| COURSE TITLE | : | ME0630 : The Layout of Piping Systems & Process Equipment |

| COURSE DATE | : | May 18 - May 22 2025 |

| DURATION | : | 5 Days |

| INSTRUCTOR | : | Mr. Andrew Ladwig |

| VENUE | : | Dubai, UAE |

| COURSE FEE | : | $ 5500 |

| Request For Course Outline | ||

Course Description

This practical and highly-interactive course includes various practical sessions and exercises. Theory learnt will be applied using our state-of-the-art simulators.

This course will familiarize engineers, designers and construction personnel with layout, design procedures and practices involved in the location of equipment and layout of piping systems. Traditionally there has been little formal training in this area and design decisions have to be made based on practical considerations without formulae or code reinforcement.

Completing piping arrangements take up the majority of manhours in the design of a process plant and the designer is required to apply acceptable layout procedures. This is an intensive five-day course that will give attendees the background required to complete a typical equipment layout and piping arrangement.

The course will also highlight the equipment layout and plot plans; civil, structural, electrical, instrumentation and maintenance considerations; distribution systems; pipe racks; pumps and piping, layout at horizontal centrifugal, vertical inline, double suction, positive displacement, performance characteristics, maintenance, cavitation, suction piping considerations, strainers, valving, parallel layouts, series layouts, supports, loads at nozzles.

During this interactive course, participants will learn the heat exchanger piping, maintenance requirements, shell and tube, plate, fin fan, valving, T.E.M.A. standards; horizontal and vertical vessels, placement, nozzle orientation, internals, platforms, ladders, manholes, maintenance requirements, valving, instrumentation, process considerations; and the process and utility piping.

link to course overview PDF

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies:

LecturesPractical Workshops & Work Presentations

Hands-on Practical Exercises & Case Studies

Simulators (Hardware & Software) & Videos

In an unlikely event, the course instructor may modify the above training methodology for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable:

| Certificates | : | Only soft copy certificates will be issued |

| Training Materials | : | Only soft copy materials will be issued |

| Training Methodology | : | 80% theory, 20% practical |

| Training Program | : | 4 hours per day, from 09:30 to 13:30 |

RELATED COURSES

ME0114(AD4) : Bearing and Bearing Failure Analysis

- Date: Aug 03 - Aug 07 / 3 Days

- Location: Al Khobar, KSA

- Course Details Register

ME0689 : Instrument and Utility Air Compressor Operation and Maintenance

- Date: Aug 03 - Aug 07 / 3 Days

- Location: Dubai, UAE

- Course Details Register

ME0077 : Control Valves, Actuators and Positioners

- Date: Aug 03 - Aug 07 / 3 Days

- Location: Al Khobar, KSA

- Course Details Register

ME0137 : Tank Design, Construction, Inspection & Maintenance

- Date: Aug 03 - Aug 07 / 3 Days

- Location: Al Khobar, KSA

- Course Details Register