COURSE OVERVIEW

FE0763-7D : Basic NDT Level II (MT, PT, & UT)

OVERVIEW

| COURSE TITLE | : | FE0763-7D : Basic NDT Level II (MT, PT, & UT) |

| COURSE DATE | : | May 18 - May 26 2025 |

| DURATION | : | 9 Days |

| INSTRUCTOR | : | Mr. Luis Lopez |

| VENUE | : | Doha, Qatar |

| COURSE FEE | : | $ 8500 |

| Register For Course Outline | ||

Course Description

This practical and highly-interactive course includes various practical sessions and exercises. Theory learnt will be applied using our state-of-the-art equipment.

This course is developed by Haward Technology in order to provide participants with the theoretical and practical training in the subject and certify them as an “ASNT Level-II” in the following Non-Destructive Testing (NDT) methods:-

a) Magnetic Particle Testing (MT)

b) Liquid Penetrant Testing (PT)

c) Ultrasonic Testing (UT)

The course is developed in compliance with the requirements of the American National Standards Institute (ANSI) and The American Society for Non-destructive Testing (ASNT) based on the ANSI/ASNT CP-105 Standard for qualification of non-destructive testing personnel and as per the ASNT Recommended Practice No. SNT-TC-1A for Personnel Qualification and Certification in Non-destructive Testing together with the extra specific requirements.

This covers the principles and theory of magnetic particle testing including magnets and magnetism; the flux fields, effects of discontinuities on materials and magnetization in circular and longitudinal field by means of electric current; the demagnetization procedures and the various types of equipment; the types of discontinuities in casting, ingots, wrought sections, parts and in welds; and the systematic evaluation techniques using various standards and appraising the defect.

Further, the course will also discuss the basic principles and process of various methods and equipment; the appropriate penetrant testing method and the discontinuities inherent in various materials, reason for indications, appearance of indications and time for indications to appear; the persistence of indications, effects of temperature and lightning, effects of metal smearing operations, preferred sequence for penetrant inspection and part preparation; the factors affecting indications for pre-cleaning, penetrant used, prior processing and technique used; the indications from cracks occurring during solidification, processing and service; and the indications from porosity and specific material forms that include forgings, castings, plate, welds and extrusions.

Moreover, the course covers true indications evaluations, false indications, relevant indications and non-relevant indications; the process control, control process variables, testing and maintaining materials; the proper inspection procedures and standards including applicable methods/processes and acceptance criteria; the basic methods of instruction; the ultrasonic technique, principle of ultrasonic, equipment, testing techniques and calibration; the evaluation of base-material product forms that include ingots, plate, sheet, bar, rod, pipe, tubular products, forgings and castings; and the composite structures and other product forms as applicable b rubber, glass, etc.

During this interactive course, participants will learn the evaluation of weldments, welding processes and weld geometries; the welding discontinuities, origin and typical orientation of discontinuities, response of discontinuities to ultrasound and applicable codes/standards; evaluating bonded structures through manufacturing processes, types of discontinuities, origin and typical orientation of discontinuities, response of discontinuities to ultrasound and applicable codes/standards; detecting discontinuity and identifying sensitivity to reflections, resolution, determination of discontinuity size and location of discontinuity; and the comparison procedures and object appraisal.

Sample Questions for general examinations are presented in the separate question booklets that can be obtained from ASNT International Service Center. Participants will further demonstrate familiarity with and ability to operate the necessary equipment for MT, PT and UT, record and analyse the resultant information to the degree required as well as test flawed specimen and component and analyse the results of NDT as part of the practical training.

At the completion of the course, participants will be appearing for a Level II exam. Each candidate will be a “Certified ASNT NDT Level-II in MT, PT & UT” upon successfully passing the examination with a minimum passing composite grade of at least 80 percent (%) which will be administered and graded by Haward Technology through its Certified ASNT Level-III instructors.

link to course overview PDF

TRAINING METHODOLOGY

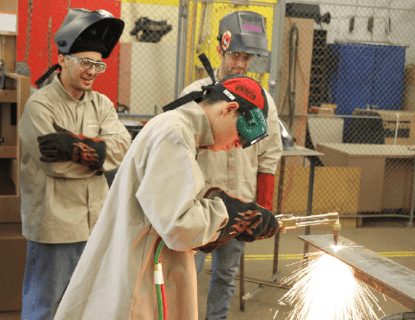

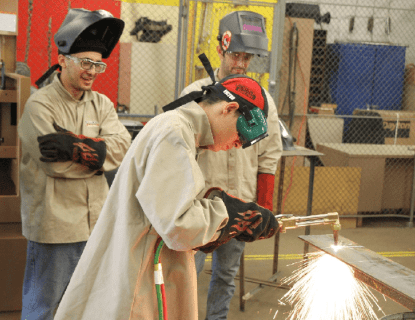

This interactive training course includes the following training methodologies:

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable:

| Certificates | : | Only soft copy certificates will be issued |

| Training Materials | : | Only soft copy materials will be issued |

| Training Methodology | : | 80% theory, 20% practical |

| Training Program | : | 4 hours per day, from 09:30 to 13:30 |

RELATED COURSES

FE0430 : Welding Engineering and Technology: ASME IX Welding, Fabrication, Brazing, Inspection & Fusing Qualification

- Date: Feb 24 - Feb 28 / 3 Days

- Location: London, United Kingdom

- Course Details Register

FE0762 : Acoustic Emission Testing Level II Training & Certification (ASNT's, SNT-TC-1A)

- Date: Feb 23 - Feb 27 / 3 Days

- Location: Kuala Lumpur, Malaysia

- Course Details Register

FE0430 : Welding Technology: ASME IX Welding, Fabrication, Brazing, Inspection & Fusing Qualification

- Date: Feb 24 - Feb 28 / 3 Days

- Location: London, United Kingdom

- Course Details Register

FE0320 : Metallurgy, Corrosion and Prevention of Failures: Material Selection and Properties

- Date: Feb 23 - Feb 27 / 3 Days

- Location: Al Khobar, KSA

- Course Details Register